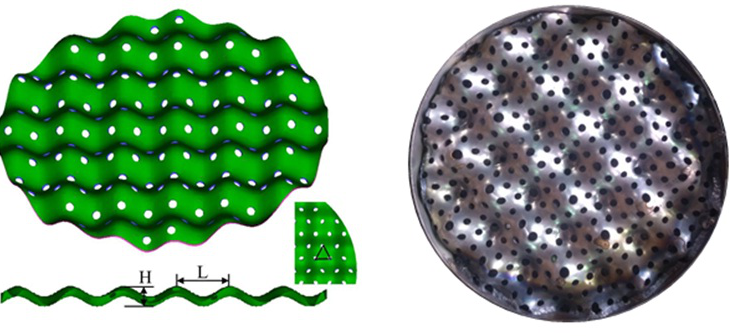

Proprietary Products of Column InternalsProprietary Products of Column InternalsTechnical team of MGHS develops and cooperates to develop a number of tower internals proprietary products. It plays a key role in strengthening the mass transfer elements in the tower, mainly including: Multi overflow downcomer TechnologyMulti overflow downcomer TechnologyThrough years of technical accumulation and experimental research, the technical team of MGHS has mastered the theoretical calculation and analysis of four passes, six passes and other multi-downcomer tray, as well as the engineering design technology of key complex structures, so as to realize the successful application of large multi-downcomer tray engineering. Relevant technologies are well applied in Dongguan Grand Resource Co., Ltd. PDH project and other projects undertaken by the company Hyperbolic corrugated tray technologyHyperbolic corrugated tray technologyThe technical team of MGHS has cooperated with SEI to develop the hyperbolic corrugated tray technology. Compared with corrugated tray and sieve tray, hyperbolic corrugated tray has wider operation range, larger treatment capacity and higher mass transfer efficiency. It is used to transform corrugated tray, sieve tray, float valve tray, etc. it can increase the capacity, operation flexibility and tray efficiency. Fixed-valve tray with large flux and high mass transfer efficiencyFixed-valve tray with large flux and high mass transfer efficiencyThe umbrella-shaped fixed-valve tray has the advantages of large flux, high mass transfer efficiency, good anti-clogging performance, and prevention of foaming, etc., which can effectively increase the tower capacity and separation efficiency. Vertical Sieve Tray(VST)with large fluxVertical Sieve Tray(VST)with large fluxVSThas the advantages of large flux ( vapor phase F-factor of empty tower can exceed 3.0 and has reached 3.5 in industrial application ), high operating flexibility, low pressure drop, excellent anti-clogging capacity, prevention of foaming, etc., which can operate efficiently under large towers and large liquid loads. Technology for preventing thermal expansion of large column internals under high temperatureTechnology for preventing thermal expansion of large column internals under high temperatureThe new internal structure that can absorb high-temperature thermal expansiondetermines the internal component structure size, through the thermal expansion theory calculation, which solves the problem of thermal expansion and deformation caused by the high temperature and the large-scale tower of the tower support, oil collection tank, etc., and makes engineering application of high-temperature large-scale tower internals feasible. Reinforced rectangular saddle ring packing technologyReinforced rectangular saddle ring packing technologyReinforced rectangular saddle ring is to emboss the surface of IMTP and rectangular saddle ring, which effectively enhances the strength of the packing and ensures that the packing of the higher packing bed layer will not be deformed.The surface ripples help to change the liquid flow Line, increasing the liquid retention time of the liquid phase, the mass transfer efficiency of the filler is improved, and the replacement of the IMTP filler has obvious advantages. New efficient structured packingNew efficient structured packingThe company has developed a variety of highly efficient structured packing technologies including high-flux plate mesh packing, structured extraction packing, corrugated baffle plate structured packing, etc., which have higher mass transfer efficiency and larger flux compared with traditional gauzestructured packing and corrugated plate packing. New efficient combination catalytic structured packingNew efficient combination catalytic structured packingNew efficient combination catalytic structured packing is used for reactive rectification. The catalyst is evenly wrapped in the structured packing block. The catalytic reaction and rectification are carried out simultaneously in the packing layer which can avoid uneven liquid flow, reduce gas rising resistance, and increase the total tower flux. Supporting technology for large column internalsSupporting technology for large column internalsThe application of the truss support beam technology developed by the company's technical team is the fundamental guarantee for the good support of large tower packing, trays and other internal components. |